Field-proven and high-performance aluminum recycling

Efficient processes - Safe. Flexible. Reliable.

Aluminum is a versatile light metal that is used in numerous industries - from the automotive and packaging sectors to the electronics industry. With the increasing demand for resource saving production methods, the importance of efficient recycling is also growing. Our innovative recycling process ensures that aluminum scrap is returned to the cycle safely and economically. Even challenging input materials with impurities or alloys can be processed effectively with our technology.

Highest grade purity despite difficult raw materials

Pure aluminum can be recycled almost indefinitely - with only 5% of the energy required for primary production. However, in order to meet the high quality requirements of the processing industry, precise separation and sorting is essential. Our advanced recycling plant enables virtually unmixed separation through mechanical shredding, air separation, magnetic separation and specialized sorting processes such as X-ray detection. This enables us to recover valuable aluminum fractions that can be further processed without delay.

Innovative recycling technology for maximum resource conservation

Our multi-stage recycling process ensures low-loss recovery of aluminium while minimizing the risk of fire and explosion. Thanks to a sophisticated system concept with various programmable operating modes, different material fractions can be processed flexibly.

Gentle shredding:

Instead of simply cutting the material, it is pulled apart in a controlled manner using special shredding technology. This prevents blockages and ensures that the material is exposed evenly.

Effective separation processes:

Various separation techniques such as magnetic drums, eddy current separators and air classifiers enable the removal of impurities and precise sorting by alloy.

Explosion protection through controlled conditions:

As aluminum dusts are highly flammable, our technology relies on temperature-reduced processing and sensor technology to monitor the dust concentration.

Flexible operating modes for different input materials:

Our system technology enables the processing of a wide variety of aluminum scrap thanks to individually adjustable operating modes. Depending on the material composition, the optimum processing strategy can be selected to ensure maximum purity and efficiency.

With our innovative recycling solution, we are setting new standards in sustainable aluminum recycling - efficient, safe and forward-looking. In this way, we are making an important contribution to conserving natural resources and ensuring high-quality raw material cycles.

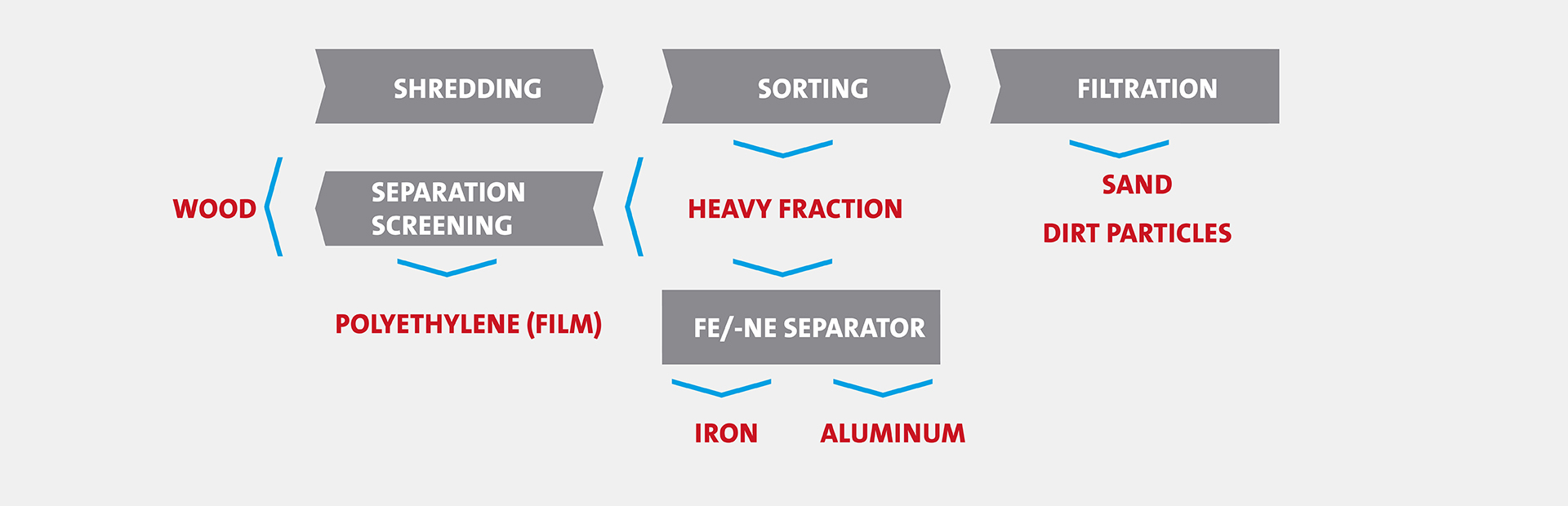

Our aluminum recycling takes place in three coordinated process steps to ensure maximum efficiency and material purity.

First, the material is coarsely crushed to prepare it optimally for the subsequent sorting processes. This is followed by separation and screening, in which unwanted components are removed and valuable metal fractions are separated. In the final step, the aluminum is precisely divided into unmixed fractions so that it can flow directly into the recycling process.

Here, the material is broken up using a powerful shredder before being passed on to the hammer mill. This combination ensures effective shredding without overheating the material or risking explosions. The controlled pulling apart of the material enables uniform material exposure and optimizes the subsequent separation.

- Effective shredding:

The ripper ensures uniform, blockage-free pre-shredding and minimizes blockages. - Hammer mill for secondary shredding:

After the initial break-up, the hammer mill further reduces the material to an optimum grain size. - Minimization of dust formation and fire hazard:

Temperature-reduced processing, in combination with sensormonitored dedusting during processing, prevents ignitable dust concentrations.

- Wind sifting:

Removes unwanted light material, e.g. wooden parts and foils. - Magnetic separation:

Separates VA and FE materials. - Screening:

Various screening processes separate material fractions according to size and prepare the material for final separation in order to efficiently sort out impurities and expose valuable metal fractions. Various mechanical processes are used here to separate the aluminum based on size, weight and magnetic properties.

- Eddy current separator:

Separates aluminum and other conductive non-ferrous alloys from non-ferrous metals and other impurities. - X-ray detection:

Detects and separates all aluminum alloys from other alloys, such as zinc die casting. - Laser induction separation:

Analyzes and separates according to different aluminum alloys.