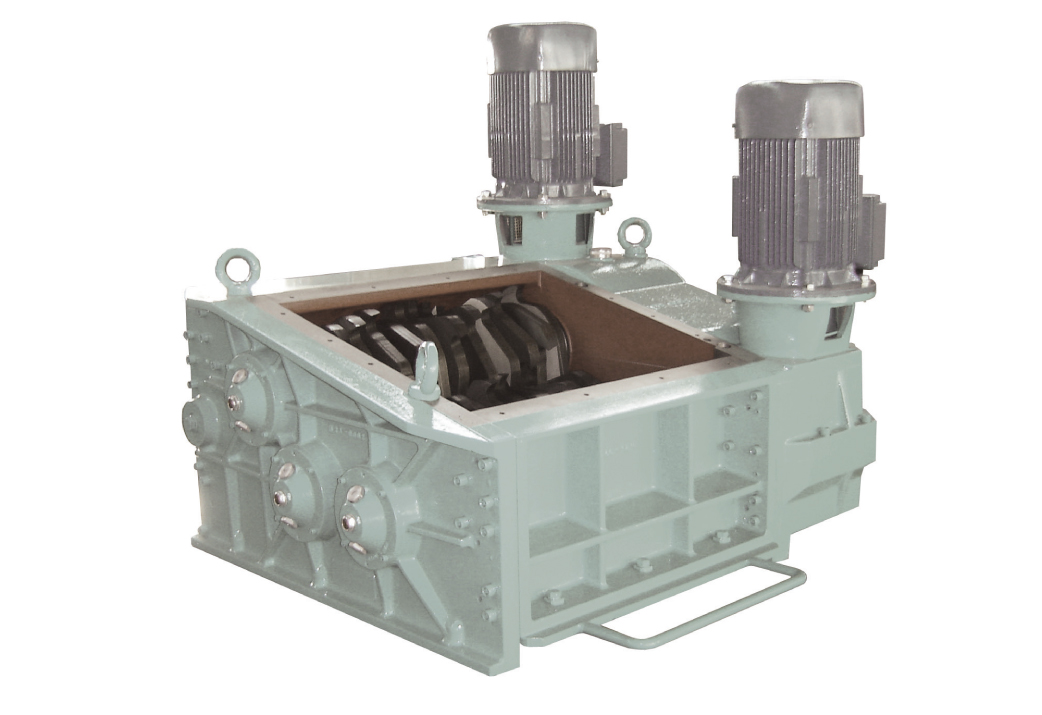

The uniform shredding of coarse materials: that’s the speciality of the Erdwich three-shaft shredder. Erdwich has created the three-shaft design especially for these requirements. Entirely free of clogging and jamming – even with solid materials. Clever, huh?

Absolutely: after all, the three cutter shafts and their individual sets of blades rotate at different speeds, so as to continuously pull in and precisely shred the feedstock material. If the material is too large, the sweeper shaft simply transfers the material to the lower cutter shafts for further size reduction. Again and again – until the material is the exact size as specified. Tirelessly, and with perfect reliability. Fragment size selection itself is achieved by the perforated screen substructure through which the material exits after the shredding process.

Precise shredding of large and solid materials. That’s what Erdwich does.

Now it’s your turn: we look forward to receiving your project inquiry!

Tightest-possible cutter spacing, ensuring energy-saving shredding without causing machine jams

Feeder shaft to ensure a maximum self-cleaning effect and reduced shaft load

Separate drives for the cutter shaft and feeder shaft

Individually fitted, replaceable cutters, spacing rings and sweepers

Central, pivotable screen basket with individual screen sections

Long service life guaranteed by cutters from custom blade steel, fully hardened to permit repeated re-sharpening

Hard-wearing screen sections from custom steel

PLC unit featuring automated reverse and power down to protect the machine against damage from overloading or solid parts

High-precision cutter assembly with cutting widths and cutter shapes tailored to the material

Tailor-made perforated screen geometries

Generously dimensioned, milled cutter shafts

Bulkhead seals to protect the shaft bearing from liquid and aggressive materials

Technical features of the three-shaft shredder:

- Rugged rotor blade cutting system with sweeper shaft

- Individually fitted, replaceable cutter discs

- Central, pivotable screen basket

- Bulkhead seals to protect the shaft bearing

- Mechanical and hydraulic drive systems available

- PLC unit featuring automated reverse and power down